Inconel and Monel are common tradenames in industry. They are two groups of superalloys which have alloys with extreme corrosion resistance. However, both types are highly expensive as well. It is because of their expensive production process.

What is Inconel?

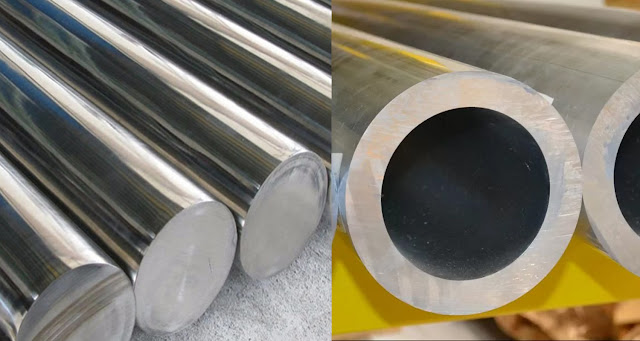

Inconel is a tradename of a group of superalloys. It contains austenitic nickel and chromium based superalloys. Manufacturers have specifically optimized these alloys in order to meet the toughest conditions during usage. In other words, Inconel has a high tolerance towards extreme heat and can keep its tensile strength at high temperatures without any change.

However, this material is expensive. In addition to tolerating extreme heat, these alloys are oxidation-corrosion resistant. When heated, this material forms a thick and stable oxide layer. And, this oxide layer can protect the surface of the alloy from further attack from heat.

Inconel is preferable over stainless steel in heat treat applications, rapid temperature changes, when exposure to salt water is required, in jet engines, etc. Moreover, this material is common in gas turbines blades, seals, high-temperature fasteners, etc.

What is Monel?

Monel is a tradename for a group of nickel-copper alloys. These alloys contain nickel predominantly with copper and few other substances including iron, manganese, carbon and silicon. The nickel content typically ranges from 52 to 67%.

Besides, this alloy is stronger than pure nickel. Moreover, it is resistant to corrosion by various agents, even by flowing sea water. The fabrication methods include hot- and cold-working, machining, and welding. More importantly, this alloy is highly expensive; for example, piping with Monel rather than carbon steel is more than 3 times expensive. Therefore, the usage of this alloy is limited.

Considering the usage, the applications of this alloy are in the field of aerospace applications, oil production, refining, marine applications, musical instruments, etc. Several grades of Monel include Monel 400, Monel 401, Monel 404, etc.

What are the Similarities Between Inconel and Monel?

- Inconel and Monel are highly corrosion resistant.

- Moreover, they are highly expensive.

- Also, both contain nickel as the predominant material.

What is the Difference Between Inconel and Monel?

Inconel is a tradename of a group of superalloys while Monel is a tradename for a group of nickel-copper alloys. Theerefore, the key difference between Inconel and Monel is that Inconel is a nickel-chromium-based alloy, whereas Monel is a nickel-copper based alloy. Moreover, the maximum nickel content in Inconel is around 72% while the maximum nickel content in Monel is around 67%.

When considering the applications, Inconel usage is common in gas turbines blades, seals, high-temperature fasteners, etc. whereas Monel is used in aerospace applications, oil production, refining, marine applications, musical instruments, etc. So, we can consider this too as a difference between Inconel and Monel.

Inconel and Monel alloy melting point

Since Inconel and monel are alloys, they do not have a specific melting point, but a melting range. The melting range of Inconel alloys is between a temperature range of 2500 - 2600°F, whereas Monel melts between a temperature range of 2372 - 2462°F.

Inconel and Monel density

The density of Monel is valued at 8.8 gm/cm3, whereas Inconel, which is lighter than monel is valued at 8.22 g/cm3

Monel and Inconel heat treatment

Inconel is generally treated by solution annealing in combination with aging. This combination is considered ideal because the mechanical properties and stress rupture properties of the alloys see a noticeable improvement. Monel, on the other hand, undergoes heat treatment by means of annealing.

The difference between Inconel and Monel hardness

The hardness of both alloys varies in different conditions. For instance, the hardness of monel in an annealed condition is lower in comparison to either hot finished condition or in a cold drawn condition. It is the same for Inconel alloys as well. However, compared to Inconel alloys, the hardness for monel is much lower.

Inconel and Monel temperature range

Although monel alloys are functional at sub-zero temperatures, these alloys cannot be used beyond elevated temperatures of 1000° F. Similar to monel, Inconel alloys deliver a good performance at low temperatures. However, due to a higher content of nickel in their alloys, most Inconels function well at elevated temperatures that range between 1200° F to about 2200° F, which is almost twice that of monel alloys.

Inconel and Monel yield strength

The yield strength of monel is lower than Inconel alloys. For instance, the yield strength of monel 400 offset at 0.2% is about 40Ksi, while the value for Inconel 625 stands at 65Ksi.

Comments

Post a Comment